Humanoid robots are no longer the stuff of science fiction. Recently, they’ve transitioned from research labs to real-world workplaces. At the forefront of this shift, a humanoid robot company has partnered with manufacturers and technology suppliers to enhance manufacturing efficiency. This collaboration marks a significant move from prototypes to production, demonstrating how these robots can alleviate tasks that traditionally slow down assembly lines and burden human workers.

The Importance of Collaboration in Manufacturing

Factories often grapple with repetitive tasks that hinder production and exhaust workers. Finding skilled labor for these roles is increasingly challenging, and injuries remain a risk. While industrial robots have helped, they are often static and designed for specific tasks. Humanoid robots introduce a new level of adaptability—they can walk, balance, and handle tools in environments designed for humans.

However, integrating these robots isn’t straightforward. Each factory has its own unique operations, requiring careful collaboration between the humanoid robot company, manufacturers, and tech partners. This team effort involves studying each site to understand worker interactions and workflow bottlenecks. Robots are then customized to fit seamlessly into existing processes, enhancing productivity without disruption.

Enhancing Factory Work with Humanoid Robots

Humanoid robots offer more than just speed—they provide flexibility. Unlike traditional robots that need dedicated cages or custom setups, humanoid robots can move between tasks in human-centric spaces. This capability allows them to handle tasks like unloading pallets, transporting materials, feeding parts into machines, and performing inspections.

A key benefit of this collaboration is reduced downtime. When human workers take breaks, humanoid robots can continue handling essential tasks. They are especially beneficial in environments with long or overnight shifts.

Safety is another advantage. By taking on tasks involving awkward postures, repetitive strain, or heavy lifting, humanoid robots help reduce workplace injuries, allowing human workers to focus on higher-value activities. This balance not only accelerates production but also boosts employee morale and retention.

Humanoid robots are designed to work alongside humans rather than replace them. Their ability to move safely, detect nearby workers, and respond to cues makes them ideal for shared workspaces. This collaborative approach facilitates automation without alienating employees.

Overcoming Challenges Through Strategic Partnerships

Introducing humanoid robots into manufacturing presents challenges. Factories are diverse, and not every task suits a robot yet. Technical challenges include ensuring robots can grasp irregular parts or identify defects. Culturally, some workers may be wary of new technology, fearing job displacement.

This is where the partnership between the humanoid robot company and its collaborators becomes crucial. By engaging with factory managers and operators, the company gathers feedback to refine robot operations. Training and demonstrations educate workers, reassuring them that their roles are evolving, not disappearing.

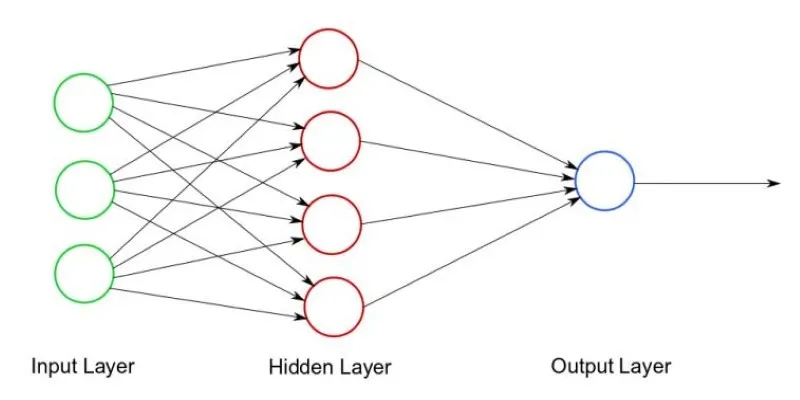

Technology partners address technical issues by integrating advanced cameras, AI algorithms, and improved battery systems. Cloud connectivity supports ongoing monitoring and updates, allowing robots to improve based on real-world data.

These partnerships enable faster deployment, adaptation to unique conditions, and build confidence among managers and workers. Without collaboration, adoption would likely be slower and fraught with setbacks.

The Future of Humanoid Robots in Industry

This collaboration is an early but pivotal step toward widespread adoption of humanoid robots in manufacturing. As experience with these machines grows, factories are discovering not only faster production but also enhanced resilience and flexibility. Over time, technology costs are expected to decline, making it accessible to smaller manufacturers.

The humanoid robot company plans to expand partnerships beyond traditional manufacturing, exploring sectors like warehousing, logistics, and construction. As robot capabilities advance, their role in supporting, rather than replacing, human ingenuity becomes more prominent.

Currently, the focus remains on manufacturing, where every minute saved and error reduced is vital. The collaboration helps factories manage labor shortages, meet rising demand, and enhance worker safety, all while maintaining efficient production lines.

Conclusion

Through strategic partnerships with technology suppliers and manufacturers, the humanoid robot company demonstrates that innovation succeeds best when integrated into real-world settings. The goal is simple: help people work smarter and faster. This human-centered approach ensures that the promise of humanoid robots is about smarter work methods, not machines taking over. As these collaborations expand, factories worldwide will likely experience significant benefits in productivity and workforce satisfaction.

zfn9

zfn9