Toyota is advancing its manufacturing processes by integrating artificial intelligence into its plants. Through strategic partnerships with technology firms, Toyota is developing AI-powered smart factory tools to enhance vehicle production. These tools aim to make production lines more precise, adaptive, and efficient, meeting modern demands while upholding Toyota’s high standards.

Embracing AI for Manufacturing Excellence

Toyota, renowned for its lean production system, has set benchmarks for efficiency and reliability. However, in today’s fast-paced industry, markets shift rapidly, supply chains are fragile, and customer expectations are ever-increasing. To maintain its leadership, Toyota is turning to AI-driven smart factory software to boost flexibility and informed decision-making. These tools analyze real-time data, identify issues early, and adjust operations instantly to ensure smooth production.

Predictive Maintenance and Quality Control

One significant benefit of AI is predictive maintenance. While machines naturally wear down, AI detects subtle signs of trouble that humans might miss. By scheduling repairs proactively, Toyota minimizes downtime. Quality control is also enhanced as AI-equipped cameras and sensors monitor every step, catching even minor flaws in real-time. This results in fewer wasted materials and superior products.

Energy Efficiency and Sustainability

AI also plays a role in reducing energy waste. By tracking power usage throughout the factory and recommending smarter operational methods, AI contributes to both cost savings and environmental conservation. This initiative reflects Toyota’s commitment to balancing productivity with sustainability, meeting demand while conserving resources.

Implementing AI-Powered Smart Factory Tools

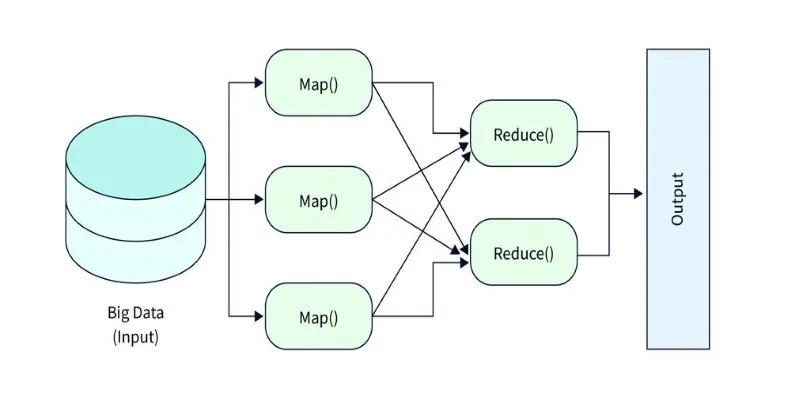

Toyota’s smart factory tools are designed to integrate seamlessly with existing production systems. The rollout begins with pilot programs in select facilities before expanding to more plants. At the core are machine learning algorithms that analyze production data and recommend real-time adjustments. For instance, if robotic arms deviate from their path or a machine shows inefficiency signs, the system can make immediate corrections.

Collaborative Robots and Human Insight

The introduction of collaborative robots, or cobots, marks another advancement. These robots work alongside human employees, using AI to learn from human tasks and lighten workloads while improving accuracy and speed. Instead of replacing workers, cobots support them, enabling employees to focus on decision-making and oversight.

Enhancing Supply Chain Management

The new tools will also optimize supply chain monitoring. Real-time tracking of inventory and supplier shipments helps avoid production delays. If issues arise, the system can automatically adjust schedules or suggest alternative suppliers, ensuring a stable, efficient production process even amidst global supply chain challenges.

The Power of Collaborative Innovation

Toyota collaborates with several technology and software companies to develop these advanced tools. While not all partner names are disclosed, they bring expertise in AI, industrial automation, and systems integration. These partnerships empower Toyota to tailor tools to its unique production environment, while partners handle technical development.

Shaping the Future of Manufacturing

Toyota’s investment in AI-powered smart factory tools could set a precedent for the industry. As a leading automaker, Toyota’s initiatives often inspire others to adopt similar strategies. If successful, this initiative promises more efficient, precise, and adaptable production, encouraging other manufacturers to launch their AI programs.

Transforming Roles and Sustainability

The shift towards AI and automation will transform factory roles, moving employees away from repetitive tasks to roles requiring judgment and oversight. Workers will remain essential in ensuring smooth operations, focusing on supervising machines and making strategic decisions. From an environmental perspective, these tools can reduce emissions and waste, aligning profitability with responsibility and promoting sustainable production.

Conclusion

Toyota’s initiative to develop AI-powered smart factory tools with technology specialists marks a significant step toward the future of manufacturing. Integrating intelligent systems with traditional production lines promises a factory that learns, adapts, and improves over time. With closer coordination between workers, machines, and data, Toyota aims to produce cars with greater precision and fewer disruptions. Beyond strengthening its operations, Toyota’s approach could influence manufacturing practices across the industry, blending proven methods with innovative thinking for smarter, more sustainable vehicle production.

zfn9

zfn9