Machines never complain—until they break down. That’s the harsh truth manufacturers have lived with for decades. In a world where every minute of downtime drains money, waiting for a breakdown is no longer an option. That’s where AI in manufacturing quietly changes everything. Instead of reacting to failures, factories are learning to stay one step ahead.

Predictive maintenance is not some futuristic dream—it’s happening right now on real factory floors. It listens when machines whisper signs of trouble and acts before small problems grow big. In this new era, smart technology keeps production moving without surprises.

How Does AI in Manufacturing Power Predictive Maintenance?

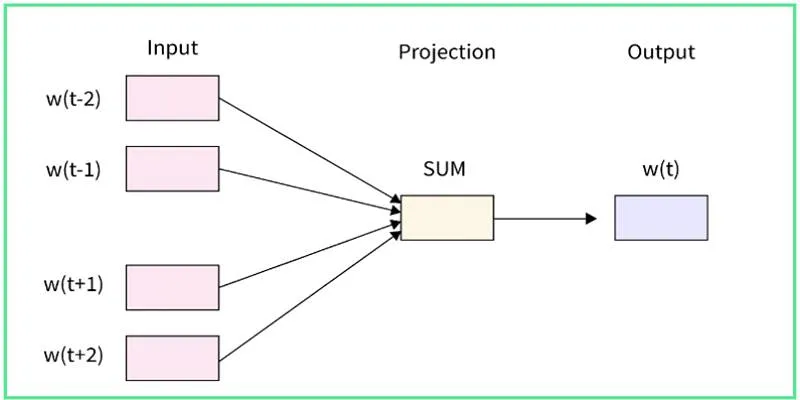

AI in manufacturing has stepped into a powerful role—it listens, watches, and learns from machines. Every piece of equipment in a factory generates data: vibrations, temperature changes, energy use, noise levels, and more. Previously, this data was just noise in the background. But AI systems today can analyze these signals in real-time.

Predictive maintenance uses AI models to spot tiny changes that humans or basic sensors might miss. For example, if a motor starts vibrating just a little more than usual, it might not seem like a problem. But AI knows that this small shift could mean a bigger failure down the road.

This approach means manufacturers can stop guessing about maintenance. Instead of wasting time on unnecessary checks or waiting for things to break, they act only when necessary. Machines run longer, parts last longer, and downtime becomes rare. AI in manufacturing doesn’t just watch for trouble—it prevents it.

Benefits Beyond Reducing Downtime

Predictive maintenance isn’t merely about avoiding equipment failure. Its effects span far beyond the factory floor. Perhaps the most self-evident advantage is cost savings. Emergency repairs come with a heavy price tag. They may call for expedited parts orders, overtime labor by employees, or even shutting down production. Preventing these issues early on spares predictive maintenance of these expenses.

It also aids in safety. Suddenly failing equipment can lead to injury. A factory with machines under constant watch is a safer working environment. Workers have confidence in the system, knowing that technology is present to avoid accidents.

There’s also the matter of resource management. AI in manufacturing makes factories more efficient. Predictive maintenance reduces the need for extra parts storage since components are only ordered when truly necessary. It lowers energy consumption because well-maintained machines don’t have to work as hard. The result is a cleaner, more sustainable operation—a concern many modern manufacturers care deeply about.

Another major benefit is production planning. When a company knows its equipment is healthy, it can plan better. There are fewer production delays, smoother supply chains, and better delivery times for customers. Predictive maintenance gives factories quiet confidence—the kind that comes from having fewer surprises.

Challenges in Implementing Predictive Maintenance

While the rewards of AI in manufacturing are clear, applying predictive maintenance is not without its difficulties. Not every factory is ready for the shift. Older machines often lack the sensors or data collection tools needed for AI systems to work properly, and retrofitting equipment can be costly and time-consuming.

Data quality is another hurdle. AI models rely on good data to make accurate predictions. Inconsistent or missing data can lead to false alerts or missed warnings. It takes time to train AI systems properly, especially in complex environments where machines may operate differently depending on conditions like temperature, load, or usage patterns.

There’s also the human factor. Skilled workers are essential to interpret AI’s recommendations and take action. Maintenance teams need to trust the system and understand its findings. This often requires new training programs and a shift in workplace culture. People have to work alongside the technology, not against it.

Privacy and cybersecurity concerns can also arise. The more connected machines are, the more vulnerable they can become to cyber threats. Manufacturers must invest in security measures to protect sensitive operational data from outside attacks.

Yet despite these obstacles, the long-term value of predictive maintenance keeps drawing manufacturers toward AI-powered solutions. The initial investment pays off when machines run longer, safer, and cheaper.

The Future of AI in Manufacturing and Predictive Maintenance

The future of AI in manufacturing looks set to be even more transformative, with predictive maintenance becoming a standard practice rather than just a helpful tool. Instead of asking whether to use AI, manufacturers will focus on how much of their processes can be automated and optimized. As AI technology continues to advance, it will become faster, smarter, and more affordable, allowing even small and medium-sized manufacturers to adopt predictive maintenance systems with ease.

Cloud-based platforms are already enabling companies to use advanced AI tools without needing heavy infrastructure. Technologies like digital twins—virtual replicas of machines—will provide even more precise monitoring and simulation capabilities, helping factories move from reactive to fully proactive operations.

In the future, AI in manufacturing may lead to self-healing systems where machines not only detect problems but also fix them automatically. This would mean parts being ordered, repairs scheduled, and production adjusted without human input. However, human expertise will still be vital. Skilled workers will take on new roles as strategic operators, managing and supervising these smart systems. Ultimately, AI will not replace people but will empower them to work smarter, ensuring factories operate efficiently, safely, and with minimal disruptions.

Conclusion

AI in manufacturing has made predictive maintenance a vital part of modern factories. It helps prevent costly breakdowns, improves safety, and ensures smoother production. While challenges exist, the long-term benefits far outweigh them. Factories today are moving beyond traditional maintenance methods, relying on smart systems that detect problems early. This shift is not just about saving money—it’s about creating safer, more efficient workplaces. Predictive maintenance powered by AI is shaping the future of manufacturing, making operations smarter and more reliable.

zfn9

zfn9