In today’s fast-paced and competitive business environment, effective supply chain management is more crucial than ever. Companies are constantly under pressure to deliver products quickly, minimize costs, and adapt swiftly to unexpected challenges. One of the most effective strategies to achieve these goals is by leveraging artificial intelligence (AI) in the supply chain.

AI-driven technologies help businesses streamline processes, enhance visibility, improve decision-making, and ultimately drive supply chain excellence. From inventory forecasting to real-time delivery tracking, AI is transforming traditional supply chains into agile, responsive systems. This post explores how AI contributes to supply chain optimization and performance and how companies can adopt AI tools to stay ahead of the competition.

The Growing Role of AI in Modern Supply Chains

Once considered futuristic, Artificial Intelligence is now a practical tool used across various industries. In supply chain operations, AI offers the ability to analyze large volumes of data, automate decision-making, and identify inefficiencies in real-time. By integrating AI into their supply chain processes, organizations can shift from reactive to proactive management.

Key Applications of AI in Supply Chain Operations

- Predictive demand forecasting

- Smart inventory and warehouse management

- Route optimization for logistics

- Supplier risk assessment and monitoring

- Automated procurement and planning

These applications enable businesses to respond to changing customer needs, reduce costs, and improve reliability across their operations.

AI Applications Across the Supply Chain

AI can be utilized at every stage of the supply chain. Let’s break down its impact in key areas:

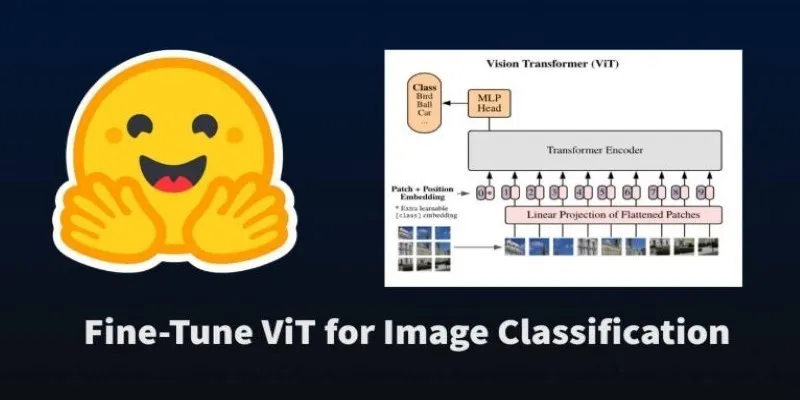

Demand Forecasting

AI models analyze sales history, seasonality, customer behavior, and external factors (like weather or news trends) to help companies forecast demand more accurately.

- Reduces overproduction and understocking

- Aligns production with market needs

- Minimizes waste

Inventory Management

Managing stock levels is challenging. Excess inventory ties up capital, while shortages can lead to missed sales. AI uses predictive analytics to find the optimal balance.

- Suggests reorder points

- Tracks slow-moving or obsolete items

- Automates replenishment

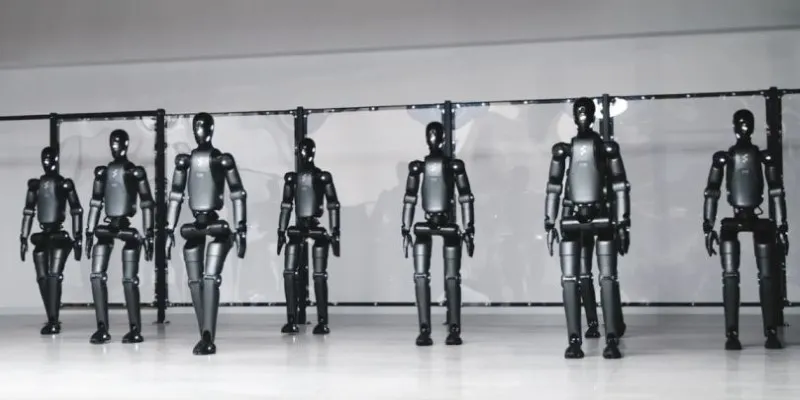

Warehouse Operations

AI-powered robots and smart systems enhance warehouse speed and accuracy.

- Automates picking, packing, and sorting

- Reduces human error

- Optimizes storage space

Supplier and Vendor Management

AI tools evaluate suppliers based on performance, delivery times, and quality, helping businesses choose the best partners.

- Identifies risky vendors

- Tracks compliance and performance

- Suggests alternatives in case of disruptions

How AI Improves Logistics and Delivery

Transporting products involves many moving parts. AI streamlines this process by optimizing routes and monitoring deliveries in real-time.

Route Optimization

AI utilizes traffic data, weather, fuel costs, and delivery schedules to create the fastest and most cost-effective routes.

- Saves time and fuel

- Reduces shipping costs

- Improves delivery reliability

Real-Time Tracking and Visibility

Customers and businesses want to know the status of their products at any time. AI enables real-time tracking and alerts for delays, increasing transparency and building customer trust.

Risk Management with AI

Disruptions such as pandemics, natural disasters, or political conflicts can impact supply chains. AI helps businesses prepare for these risks by analyzing patterns and past data.

How AI Supports Risk Management:

- Monitors global events that could affect supply chains

- Predicts the impact of disruptions

- Recommends backup plans and alternative suppliers

This proactive planning leads to stronger and more resilient supply chains.

Using AI to Support Sustainability Goals

Today’s businesses face pressure to be more sustainable. AI aids in achieving these goals by reducing emissions, energy usage, and waste through smart data analysis.

How AI Boosts Sustainability in Supply Chains:

- Plans greener transport routes

- Reduces packaging waste

- Cuts down energy usage in warehouses

- Identifies suppliers with eco-friendly practices

By making small changes based on AI insights, companies can reduce their carbon footprint without impacting profitability.

Common Challenges in Implementing AI

While AI offers numerous benefits, some challenges must be addressed.

Data Quality and Availability

AI requires clean, complete data to function effectively. Many companies struggle with siloed systems or missing data.

Change Management

Adopting new AI tools can be challenging for employees. Training and support are essential for successful implementation.

Cost of Technology

AI systems require an upfront investment. However, the long-term savings often outweigh the initial costs.

Best Practices to Drive AI Success in Supply Chains

To maximize AI benefits, companies should adhere to a few key best practices:

- Start small : Begin with one area, such as forecasting or warehouse automation.

- Clean your data : Ensure your data is accurate and well-organized.

- Use the right tools : Choose AI tools that fit your business size and goals.

- Train your team : Educate your staff on how AI works and how to use it effectively.

- Monitor performance : Use dashboards and KPIs to track improvements over time.

Real-World Example

Consider the case of a large retailer. Before implementing AI, they frequently ran out of popular products and overstocked items that didn’t sell.

After adopting AI-powered forecasting tools, they:

- Reduced excess inventory by 30%

- Improved on-time deliveries by 20%

- Cut down on waste and saved money

This example illustrates how even small changes can lead to significant improvements with AI.

Conclusion

AI is revolutionizing supply chain operations by making them smarter, faster, and more efficient. With better forecasting, real-time tracking, and predictive insights, businesses can reduce waste and improve customer satisfaction. AI also supports sustainability and resilience in uncertain times. While challenges like data quality and cost exist, the long-term benefits far outweigh them. Starting small and scaling gradually is key to success. With the right tools and mindset, AI can transform any supply chain. Embracing this technology today ensures competitiveness in the future.

zfn9

zfn9