Supply chain operations have become more complex than ever. From raw material sourcing to customer delivery, each stage involves countless decisions, data points, and potential disruptions. To handle this rising complexity, many businesses are turning to Artificial Intelligence (AI) to improve how their supply chains work.

Embedding AI across supply chain processes involves using smart technologies that help companies predict demand, manage inventory, optimize routes, and reduce risks. Rather than relying on guesswork or slow manual methods, AI allows supply chains to be faster, more accurate, and more cost- efficient.

Why AI Is Now Essential in Supply Chains

AI isn’t just a tool anymore; it’s quickly becoming essential. Global supply chains are expected to be adaptable and robust, but challenges like sudden demand shifts, international unrest, and rising transportation costs make this difficult. AI can identify trends, suggest actions, and automate routine tasks by analyzing vast amounts of data. It helps everyone in the supply chain make smarter decisions and perform better.

Key Areas Where AI Can Be Embedded

Companies can embed AI into almost every stage of the supply chain, aiming to create a connected system where information flows smoothly and decisions are based on real-time insights.

Demand Forecasting

AI uses historical sales data, seasonal patterns, weather conditions, and market trends to predict future demand. These predictions help companies avoid stockouts and overproduction.

Benefits:

- Improved planning

- Reduced waste

- Increased customer satisfaction

Inventory Management

With AI-powered tools, businesses can monitor stock levels, track movement, and set automatic reorder points. AI helps prevent both overstocking and understocking.

Benefits:

- Lower holding costs

- Better use of storage space

- More accurate stock visibility

Procurement and Supplier Management

AI can evaluate supplier performance , compare prices, and detect risks in the supply chain. It helps companies choose reliable vendors and reduce dependency on risky sources.

Benefits:

- Fewer supply chain disruptions

- Stronger vendor relationships

- Cost-effective sourcing

Production Planning

AI considers current capacity, raw material availability, and delivery deadlines to create efficient production schedules. It adjusts automatically when unexpected changes happen.

Benefits:

- Reduced downtime

- Faster order fulfillment

- Balanced workload across resources

Logistics and Transportation

AI algorithms optimize delivery routes based on traffic, weather, and delivery windows. It also predicts delivery delays and suggests faster or more affordable alternatives.

Benefits:

- On-time deliveries

- Reduced fuel costs

- Improved customer experience

Real-Life Scenarios of AI in Supply Chains

Many businesses are already seeing results by embedding AI in their supply chain processes.

Smart Route Optimization

A delivery company uses AI to plan routes for its drivers. The system updates in real-time based on road conditions, accidents, or weather. As a result, deliveries are faster, and fuel consumption is lower.

Predictive Equipment Maintenance

A manufacturing firm installs sensors on machines that send real-time data to an AI system. The system detects unusual patterns and predicts when maintenance is needed, avoiding breakdowns and keeping production running smoothly.

Step-by-Step Guide to Embedding AI in the Supply Chain

Introducing AI into the supply chain is a journey. It requires a thoughtful approach, starting with small changes and gradually expanding to more complex areas.

Step 1: Clean and Organize Data

AI systems rely on data. Businesses must first gather clean, consistent, and accurate information from different sources such as sales, warehouse systems, and transport logs.

Step 2: Choose the Right AI Solutions

Not all AI tools are suitable for every business. It’s important to pick solutions that match the company’s industry, size, and goals.

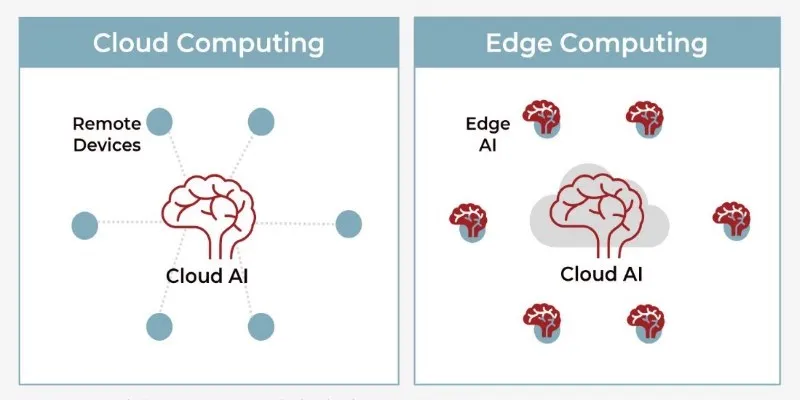

Step 3: Integrate AI with Existing Systems

AI must work smoothly with current software such as ERP, inventory management, or logistics platforms. Integration is key for real-time insights.

Step 4: Train Teams to Work with AI

Employees don’t need to be tech experts, but they should understand how to use AI tools, trust their insights, and know when to step in with human judgment.

Step 5: Start Small and Scale Gradually

Rather than overhauling the entire supply chain, companies should start with a pilot—such as using AI for forecasting or routing—and expand as confidence grows.

Benefits of a Fully AI-Driven Supply Chain

When AI is successfully embedded, the supply chain becomes more connected and responsive. The results speak for themselves:

- Better demand planning

- Less inventory waste

- Faster order fulfillment

- Lower transportation and logistics costs

- Improved supplier performance

- Real-time visibility across the chain

These benefits not only improve efficiency but also give companies a competitive edge in the market.

Common Pitfalls to Avoid

While AI offers many advantages, there are some common mistakes businesses should avoid.

Skipping Data Preparation

AI tools won’t work properly if the data is messy or incomplete. Data cleaning is a crucial first step.

Over-automation Without Human Oversight

AI is smart, but it can’t replace human judgment entirely. Decision-makers should stay involved in high-impact processes.

Ignoring Change Management

Employees may resist new systems if they don’t understand them. Clear communication and training help ease the transition. One important step between planning and execution is getting employee buy-in and addressing concerns early.

Conclusion

Embedding AI across the supply chain is not just about using new technology. It’s about building a smarter, faster, and more adaptable system. From demand forecasting and supplier management to logistics and delivery, AI can improve every stage of the supply chain. By starting with good data, choosing the right tools, and training teams to use them, companies can take the first steps toward AI-powered operations. The result is a supply chain that’s more resilient, cost-effective, and ready for the future. Now is the time for businesses to embrace AI—not just to keep up, but to lead.

zfn9

zfn9