Technology in manufacturing has rapidly evolved over the years, leading to significant transformations in recent times. Traditional manufacturing, once reliant on human labor and mechanical tools, is now transitioning into a modern, computerized industry. Technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and robotics are being integrated into production lines to boost productivity, enhance efficiency, and reduce overall costs. These advancements have paved the way for smart manufacturing systems, which leverage automation and data processing. Companies that adopt smart factory solutions are more likely to remain competitive in the Industry 4.0 landscape. This article explores the role of technology in manufacturing, highlights major changes in the field, and addresses the integration of innovation into manufacturing.

The Evolution of Manufacturing Through Technology

From Traditional to Smart Manufacturing

The transition from traditional to smart manufacturing involves moving from basic mechanical production to advanced computerized systems. Previously, labor-intensive processes resulted in high operational costs and low productivity. Today, technologies like robotics and machine learning have revolutionized manufacturing, allowing for greater efficiency and precision. Automation has become a key factor in ensuring consistent quality and minimizing defects, compared to manual labor. Smart factory solutions provide real-time monitoring and predictive maintenance, reducing losses due to equipment breakdowns. The rise of IoT in factories has enabled the digitalization of manufacturing, facilitating seamless integration and coordination of the entire production process.

Key Innovations in Advanced Manufacturing Technology

Innovation is at the heart of the modern manufacturing industry. One groundbreaking technology is 3D printing, which supports prototyping and small-scale production with minimal waste. Predictive maintenance, powered by AI, identifies potential equipment faults, preventing disruptions. Robotics and automation enhance precision, especially in the automotive and electronics sectors. Edge computing, which processes data locally on manufacturing tools rather than cloud servers, enables instant decision-making. Collectively, these innovations drive digital transformation, making manufacturing processes more efficient, cost-effective, and environmentally friendly.

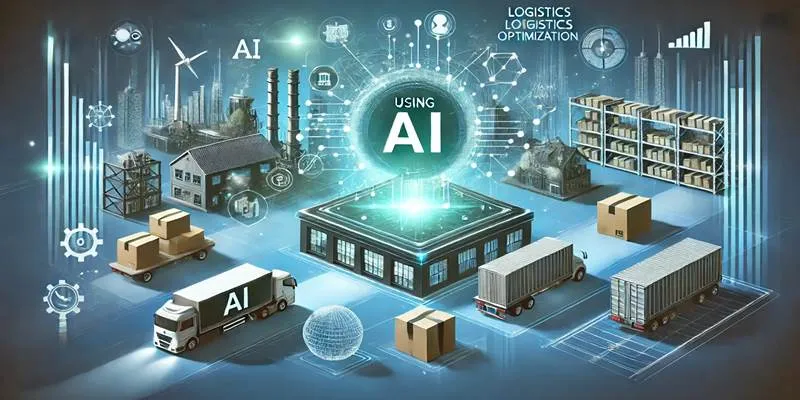

The Role of IoT in Digital Transformation in Manufacturing

The IoT plays a pivotal role in the digital transformation of manufacturing by connecting devices and sensors across production lines. IoT systems gather vast amounts of data to optimize operations. Smart sensors monitor machine performance, alerting maintenance teams before issues escalate. Real-time data on inventory and product demand enhances supply chain efficiency. By addressing resource allocation challenges and boosting productivity, IoT technology is integral to implementing digital transformation in manufacturing.

Smart Factory Solutions and Industry 4.0

Defining the Smart Factory

Smart factories represent the next generation of manufacturing, characterized by interconnected systems that exchange information in real-time and respond to product demand dynamically. These factories require minimal human intervention, leading to lower costs compared to their output levels. Advanced technologies such as digital twins, AI analytics, and Robotic Process Automation (RPA) are deployed to optimize performance in smart factories.

How Digital Twins Improve Manufacturing Efficiency

Digital twins are virtual models of manufacturing processes, products, or systems. They enable manufacturers to simulate changes and assess their impact on production without real-world implementation. This technology is crucial for optimizing product design, predicting equipment failures, and enhancing supply chain management. In industries like automotive and aerospace, digital twins facilitate virtual testing of components, reducing the risk of costly errors.

AI and Machine Learning in Smart Factories

AI and Machine Learning (ML) are transformative for the manufacturing sector, enabling data-driven decision-making. Smart factory solutions leverage AI algorithms to predict patterns and product demand, improving decision accuracy. These technologies enhance quality control by detecting defects invisible to human inspectors. AI-powered RPA streamlines repetitive tasks, reducing human workload and minimizing errors. AI also optimizes supply chain management by forecasting raw material needs, preventing wastage.

Challenges and Future of Digital Transformation in Manufacturing

Barriers to Implementing Advanced Manufacturing Technology

Despite its benefits, implementing advanced manufacturing technology presents challenges. Initial investment costs are high, deterring some companies from upgrading their production facilities. The transition to smart factory solutions requires a workforce skilled in AI, IoT, and automation. Many employees lack the technical expertise needed to operate these technologies. Additionally, the increased reliance on digital systems heightens the risk of cyberattacks.

The Future of Manufacturing Innovation

The future of manufacturing will be shaped by emerging technologies like quantum computing and nanotechnology. Quantum computing promises to revolutionize supply chain logistics, while nanotechnology will enhance material durability and efficiency. Sustainable manufacturing is gaining traction, with smart factories emphasizing energy efficiency and carbon footprint reduction. Hyper-automation, where AI, robotics, and IoT fully automate production, will redefine industrial processes.

Conclusion

Advanced manufacturing technology is transforming the industry by improving efficiency, reducing costs, and enhancing product quality. Innovations such as 3D printing, AI, IoT, and digital twins are making factories smarter and more interconnected. Smart factory solutions enable seamless automation, while AI and machine learning support informed decision-making. The future of manufacturing hinges on innovation, sustainability, and workforce adaptation. Companies embracing these advancements are poised to thrive in an increasingly competitive global market.

zfn9

zfn9