A young robotics startup is making waves by introducing a cutting-edge AI model tailored for robotic arms. This innovation promises to infuse much-needed intelligence and adaptability into machines that have traditionally relied on rigid programming. No longer confined to repetitive tasks on factory lines, robotic arms equipped with this smart AI could soon handle delicate and dynamic jobs that previously required human intervention. This advancement hints at a future where machines can adjust to unpredictable conditions rather than adhere strictly to fixed scripts.

Smarter Movement: What Sets the Model Apart?

Robotic arms have long served as the backbone of manufacturing, celebrated for their strength and precision. However, they’ve been limited by their inability to adapt on the fly. Enter the new AI model, which leverages advanced neural networks trained on vast datasets — encompassing movement patterns, object shapes, and real-world surprises — to enable robotic arms to sense and react in real-time. When faced with unexpected changes, the arm can instantly adjust, maintaining operation without errors.

The engineers aimed for more than reactive intelligence; they sought speed and fluidity. The system decides its next move in milliseconds, making its motions feel natural instead of mechanical. Remarkably, the arm learns with each task, enhancing its accuracy and adaptability. Over time, it becomes adept at recognizing and responding to subtle environmental changes, opening up possibilities for jobs that were once beyond the reach of robots, such as handling fragile products, preparing food, or operating in constantly changing conditions.

Behind the Scenes: How the Technology Works

At the core of this system is a deep-learning architecture optimized for spatial awareness and dynamic planning. Engineers have integrated high-resolution cameras and touch sensors within the robotic grippers, enabling a detailed, three-dimensional understanding of interactions. Unlike earlier models, which relied solely on vision or pre-programmed paths, this AI processes feedback in real-time.

The model incorporates reinforcement learning, where the arm experiments with different approaches and identifies the most effective strategies through trial and error. It is also capable of transferring skills across tasks. For instance, if it learns to handle soft materials like fabric, it can apply similar techniques to other delicate materials in varying settings.

A significant feature is its adaptability to variable lighting and cluttered spaces, two challenges for industrial robots. The AI has been trained to operate effectively even in dim light or when partially obstructed, enhancing reliability beyond pristine factory floors.

Applications Beyond the Factory

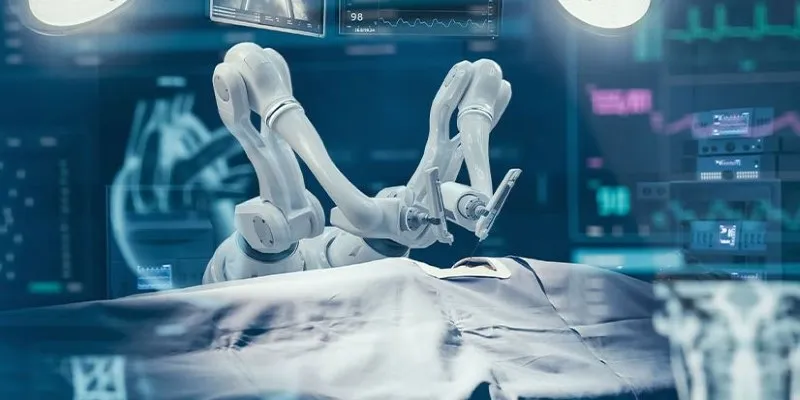

The startup envisions applications for its technology beyond traditional industrial sectors. In healthcare, robotic arms could assist in operating rooms by handing tools, holding tissues steady, or even stitching wounds with high precision. Their ability to adapt makes them ideal for the unpredictable nature of surgery compared to older systems.

Food service is another promising domain. Preparing meals involves considerable variability, with no two vegetables alike in shape or firmness. Tests show the model can grip and slice produce without damage, a capability that could revolutionize automated kitchens.

Interest is also growing in using this technology for recycling and waste sorting. Conventional machines often struggle with irregularly shaped or dirty materials, but this AI-guided arm can quickly assess an object’s shape and surface, choosing the optimal method to pick and sort it. This could significantly enhance efficiency in recycling plants, where contamination and variability are persistent issues.

What This Means for the Future of Robotics

By embedding this level of intelligence into robotic arms, the company challenges long-held assumptions about machine capabilities. Flexibility and learning, once considered uniquely human traits, are now being integrated into robotics, bridging the gap between rigid automation and nuanced human-like adaptability.

For industries, this development could lead to fewer interruptions, lower error rates, and reduced reliance on human oversight for routine tasks. For workers, it raises questions about evolving roles as machines take on responsibilities once thought beyond their reach. The startup emphasizes that its goal isn’t to replace workers but to develop tools that complement human labor, tackling tedious or physically demanding tasks.

As the technology matures, we can expect robotic arms to enter unexpected arenas — from hospitals to restaurant kitchens to disaster zones too dangerous for humans. While still in the early stages, this AI model’s ability to learn and adapt suggests a future where machines not only follow instructions but also make decisions suited to the moment.

Conclusion

The launch of this AI model signifies a major leap forward for robotics, highlighting the progress intelligent automation has achieved. By empowering robotic arms to adapt to real-world unpredictability, this technology could reshape industries and redefine how machines collaborate with humans in meaningful ways. Although challenges remain in scaling the technology and ensuring consistent performance across various settings, its potential impact is undeniable. As these smart arms become commonplace in workplaces, homes, and beyond, they could stand as some of the most visible and practical examples of how artificial intelligence is transitioning from research labs to everyday life.

zfn9

zfn9