Warehouses are evolving in ways few predicted just a decade ago. Inside modern facilities, intelligent robots now work alongside people, sorting and moving goods with speed and precision. These robots are trained with artificial intelligence, enabling them to adapt to various tasks, accurately identify items, and work more efficiently than humans could alone.

They’re no longer limited to repeating simple motions; they learn from data and improve continuously. This shift has transformed how warehouses operate, making processes smoother and more responsive to customer demand. AI-trained robots are proving to be one of the most significant advances in logistics technology.

How AI Training Improves Warehouse Robots

AI training enables warehouse robots to make decisions based on their observations and learning, rather than blindly following a fixed script. In the past, robots relied on rigid programming that couldn’t handle even small changes in their environment. If an item was misplaced or the wrong size, operations often stalled. AI-trained robots use machine learning models, sensors, and cameras to understand their surroundings and react in real time.

They scan and identify products by analyzing barcodes, shapes, and labels, while creating a digital map that updates as goods move. This allows them to work efficiently, even if inventory is rearranged or new products are introduced. AI also enables them to learn patterns over time, identifying busy periods, common mistakes, and optimal paths through the warehouse, so they can adjust and maintain a steady pace without human intervention.

These capabilities make robots more than just fast. They become dependable and flexible tools that keep operations running smoothly, even in unpredictable situations. AI helps them achieve a level of awareness that earlier machines lacked, cutting down delays and improving workflow across the entire warehouse.

The Role of Machine Learning in Speed and Accuracy

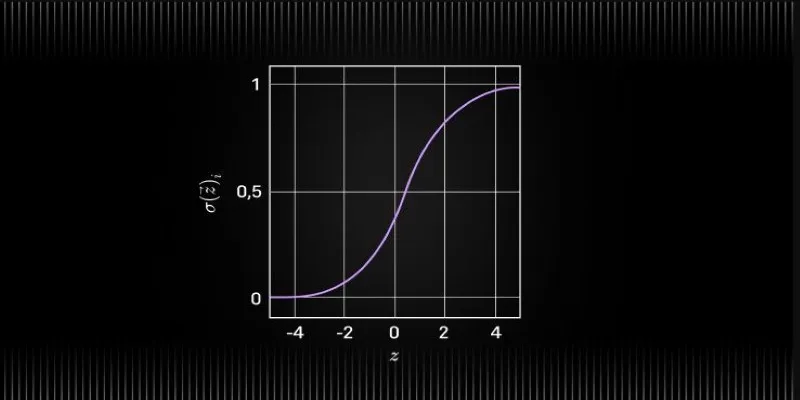

Machine learning is what makes these robots faster and more precise than earlier technology. Instead of memorizing one way to sort, the robot processes large amounts of data from past work to determine the most effective methods. During training, robots run countless simulations or live tests to see what works and what doesn’t. The results feed back into their systems so future decisions are smarter.

A trained robot can quickly identify an item, calculate the most efficient route to its destination, and execute its moves with high precision. Humans sorting by hand may take several seconds to pick and place each item. Robots trained with machine learning can reduce that time to under a second in many cases, all while minimizing mistakes.

They also learn how to handle packages of different shapes and weights without slowing down. If two boxes look similar but belong to different orders, the robot can tell them apart by recognizing fine details that humans might overlook. Robots also learn collectively. If one robot discovers a more efficient way to sort a challenging item, that knowledge can be shared with the entire fleet, improving efficiency across the warehouse.

Even during sudden surges in demand, these machines adapt. They recognize patterns from previous busy periods and adjust their behavior to maintain accuracy. This ability to self-correct and improve over time gives warehouses a clear advantage in meeting delivery deadlines without errors.

How AI-Driven Sorting Changes Warehouse Operations

The rise of AI-driven robots has changed the way warehouses are designed and operated. With machines handling the fast and repetitive sorting, human workers focus more on tasks that require judgment, maintenance, and problem-solving. Many warehouses are redesigned to suit robotic needs, with narrower aisles, higher shelves, and optimized layouts to minimize travel time. This allows more inventory to be stored and accessed quickly.

Robots working alongside people improve both speed and safety. They can lift heavy loads, operate continuously without fatigue, and detect when humans are nearby to avoid collisions. Accidents are reduced, and workers face less strain from repetitive lifting and walking long distances. As a result, warehouses can operate at a faster pace without compromising worker well-being.

Space is used more efficiently, which is valuable as storage needs grow. Robots can reach into tighter areas than people, maximizing every inch of available room. Turnaround times improve because sorting, packing, and shipping are all completed more quickly. Same-day and next-day shipping have become more common because AI-trained robots can sustain the pace required for modern retail and e-commerce.

The Future of AI in Warehouse Sorting

AI’s role in warehouse sorting will only grow as technology matures. Developers are working on ways to connect robots directly to supply chain systems so that decisions are informed not just by what’s on the shelves now, but by what’s on the way. This would allow warehouses to sort with full knowledge of incoming shipments and anticipated demand.

Future robots are likely to become better at handling delicate, irregular, or fragile items by learning how much pressure to apply and how to move carefully. Advances in machine learning could also allow robots to better understand spoken commands, making it easier for workers to interact with them directly without special training.

There are still barriers, such as the initial investment cost and the need to retrain robots when warehouses stock new products. But as the benefits continue to outweigh the drawbacks, more companies are adopting these systems. AI-trained robots are shaping the future of logistics by making warehouses faster, safer, and more reliable—a clear sign of where the industry is headed.

Conclusion

AI-trained robots are reshaping warehouses into faster, smarter, and more efficient spaces. With the ability to learn and adapt through machine learning, these machines perform sorting tasks with speed and precision beyond what humans can achieve alone. They reduce errors, save time, and allow better use of space while improving workplace safety. Warehouses now operate in ways that keep up with the growing demand for quick deliveries. As these robots become even more capable in the coming years, they will help warehouses stay ahead of the curve, combining technology and human oversight to meet the needs of a changing world.

For more insights on AI and warehouse technologies, explore our technology section.

zfn9

zfn9